WELDING

A key production activity is a process of welding, which is the reason why the company has completed the TÜV Rheinland certification for the manufacturers who provably fulfil complete quality requirements for welding according to DIN EN ISO 3834-2.

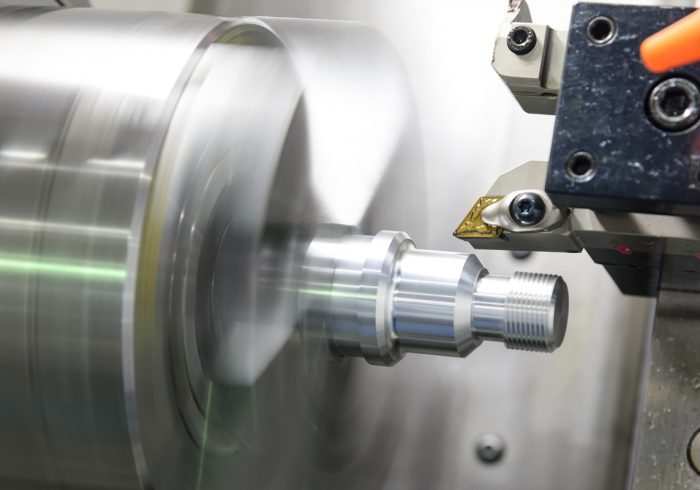

CNC MACHINING

A key production activity is a process of welding, which is the reason why the company has completed the TÜV Rheinland certification for the manufacturers who provably fulfil complete quality requirements for welding according to DIN EN ISO 3834-2.

SHEET METAL BENDING

We are able to produce a wide range of parts according to customer requirements with weights from a few grams up to 800 kg, for which we guarantee high accuracy. We focus on serial as well as custom production.

LASER 3D/2D cutting

Our company uses the LASER BODOR P3015T 2kW Laser Cutting Machine for cutting and marking, thanks to which the cut is completely smooth. Other advantages are efficiency, high cutting speed, accuracy and cut quality. We focus on cutting and marking steel, stainless steel and galvanized sheets.

SURFACE TREATMENT

We use a set of technological processes to ensure high-quality treatment of metals with epoxy and polyurethane paints, high-pressure spraying, powder coating and galvanizing.

ASSEMBLY WORKING

According to customer requirements, we perform various assembly work. We install demanding storage systems and racks and also provide construction work during assembly. Our company also deals with the installation of stairs, railings, sheds and gates.